Roof and Deck Coating

HU-100

HU-100

Two Component Hybrid Urethane Roof Coating

ProtecKote is a Two-component fast curing, Hybrid Urethane Roof and Deck Coating which upon curing forms a monolithic, flexible membrane, making it highly suitable for all types of waterproofing applications on various substrates. ProtecKote HU-100 has excellent adhesion on all suggested substrates and can also be applied on wet and damp surfaces.

ProtecKote HU-100 is a highly versatile protective coating designed for use on a diverse array of surfaces. It can be applied to concrete, metal, Spray Polyurethane Foam (SPF), Aged, Ethylene Propylene Diene Monomer (EPDM), Polyvinyl Chloride (PVC), and Thermoplastic Polyolefin (TPO) roofing membranes as a protective coating. Additionally, it is suitable for clay roof tiles, plywood, Built-Up Roofing (BUR) systems, and cap sheet etc providing adequate protection against ingress of water.

Features

- ResistanceGood resistance to the ingress of water and vapour

- AdhesionExcellent adhesion on wet and damp substrates

- AbrasionHigh resistance to abrasion

- Low VOCEnvironmentally friendly

- DurableResistant to UV degradation

- Good FlexibilityFast curing time (60mins at 77°F)

- Foot TrafficCan be subjected to light foot traffic after full cure (7 days).

- Approvals ASTM-D 6083-21 | FLORIDA FL#47542 | MIAMI-DADE COUNTY NOA NO. 25081302 | Texas Department of Insurance (TDA)

Technical Parameters

|

Properties |

Test Method |

Value |

|---|---|---|

| Color | - | White/Grey# |

| Mixed density, (g/l) | ASTM D 1475 | 1.1±0.05 |

| Solid content, (%) | ASTM D 1353 | 60 |

| Pot life, (Hrs.) | - | 6 |

| VOC, (g/l) | USEPA 24 | < 10 |

| Touch dry time, (mins) | - | 1hr |

| Initial Cure time, (mins) | - | 45 mins [ skin over time] |

| Full cure, (Hrs.) | - | 72 hrs |

| Tensile strength, psi | ASTM D 2370 | 380 |

| Elongation, (%) | ASTM D 2370 | 300 |

| Tear strength, lb/in | ASTM D 624 | 100 |

| Solar reflectance, (%) | ASTM E 1549 | ≥75 |

| Shore A Hardness | ASTM D 2240 | 45 |

| Water Vapor transmission, (perms) | ASTM D 1653 | 7 |

| Adhesion strength, (N/mm2) | ASTM D 4541 | ≥3 (cohesive failure of concrete) |

| Crack bridging ability, (mm) | ASTM C 836 | ≥4 |

| Application temperature, (°F) | - | 40-100 |

| Service temperature, (°F) | - | -4 - 150 |

Substrate Preparation

Roof must have positive drainage. Roof substrate must be clean, completely dry, and free from any free of any dirt and debris. Power-wash to remove all dust and debris and allow to dry. Examine substrate and conduct adhesion test to verify adhesion of coating prior to start, pre-stripe all flashings and penetrations, and repair before coating application commences.

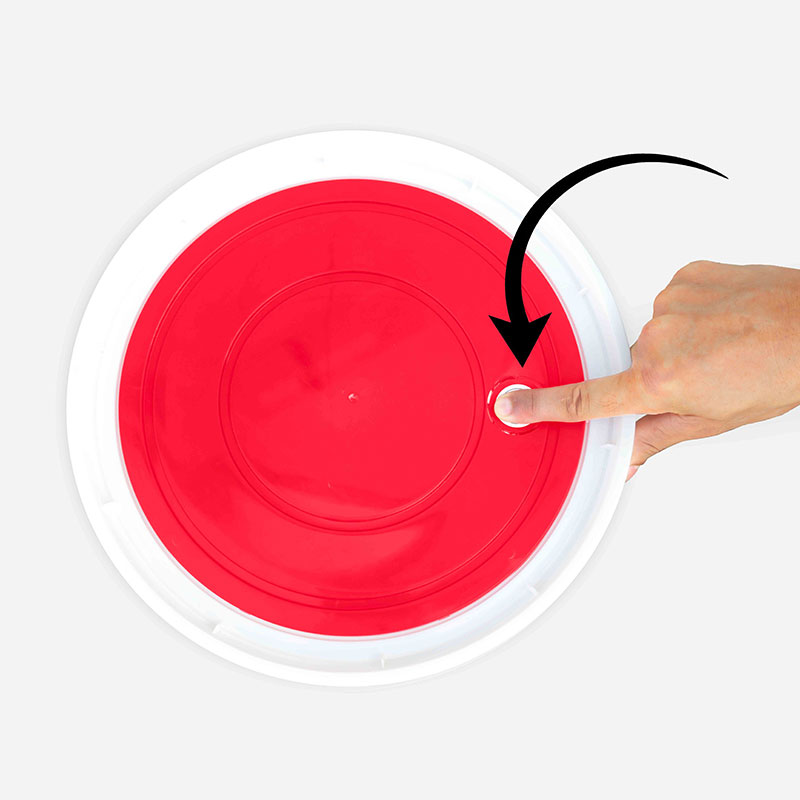

Mixing

Pour the contents of Part B (placed inside the lid) into the Part A container and mix thoroughly with a proprietary 3"(76 mm) minimum diameter mixing blades for 2 to 3 minutes until a homogenous consistency is achieved.

Application

ProtecKote HU-100 shall be applied in minimum of 2 coats. Apply The first coat of ProtecKote HU-100 on all areas with a brush / roller or spray at a coverage rate of 1.5 gallons/square. Dry Film Thickness (DFT) should be minumum of 22 mils.Apply the second coat in a perpendicular direction to the previous coat atier the previous coat dries off. Allow at least four hours between coats and 24–48 hours for full cure, dependent upon weather conditions. Relative humidity will directly affect drying/curing time. Avoid over application. Application rates should be adjusted to meet each particular roofs specified requirments. Coverage rates are theoretical and do not take into account material loss due to surface texture.

For Critical Areas: It is recommended to pre- treat all areas prior to commencement of coating. Apply the first coat of ProtecKote HU-100 with a brush on all corners and around the pipe penetrations extending up to 8 Inch on either side. A fibre mesh/geotextile fleece shall be embedde still in wet condition. Apply a second coat over it atier the previous coat dries off.

Clean-up

Clean tools with mineral spirits or paint thinner, if coating has dried. If coating is still wet, clean up with warm soapy water.

Storage and Handling

Store under cover, out of direct sunlight and protect from extreme temperatures. Do not store at temperatures below 45°F and not greater than 120°F. Keep Containers covered when not in use. DO NOT allow coating to freeze. All the mixed material should be used within 90 Minutes at 68°F or 45 Minutes at 86°F.

Shelf Life

12 months from date of Manufacture when stored as per recommedations and in unopened conditions.

Disposal

Cured ProtecKote HU-100 coatings are inert and can be disposed of in regular disposal areas. Unused materials and packag-ing materials should be disposed as per the local governing laws on disposal of hazardous goods.

Important

Do NOT heat container

DO NOT attempt to Dilute the product

Healthy and Seafty

Protective gloves and safety glasses should be used. Wash thoroughly with plenty of water if eye and skin get contaminated and seek medical advice in extreme cases.